The Rise of the Friendly Machine: Collaborative Robots

- Home

- Case Study

- The Rise of the Friendly Machine: Collaborative Robots

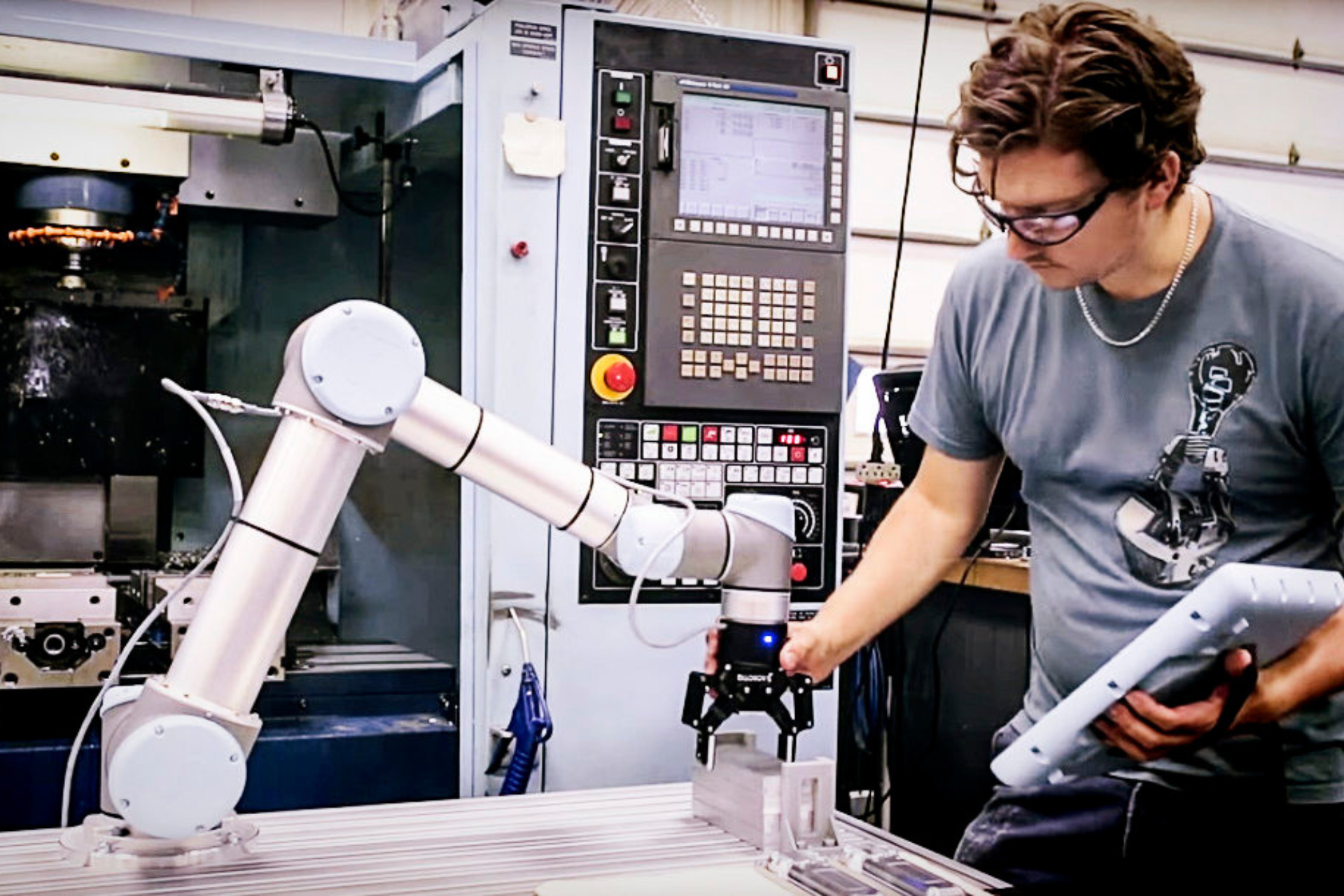

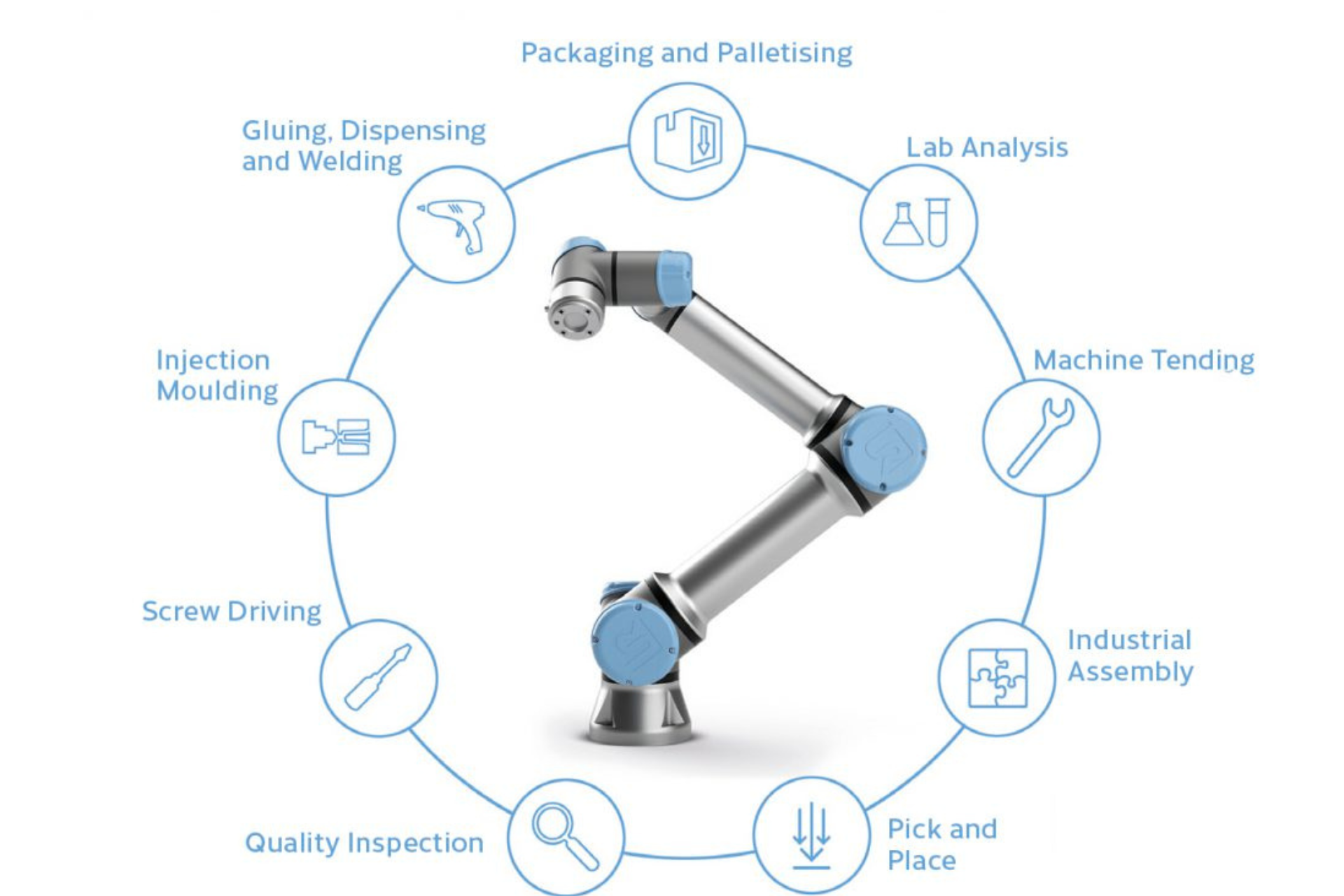

The image of industrial robots has long been one of powerful, caged machines performing repetitive tasks. However, the landscape of manufacturing is evolving. Collaborative robots, or cobots, are ushering in a new era of human-AI interaction, working alongside humans to improve efficiency and safety in factories.

What are Cobots?

Unlike traditional industrial robots, cobots are designed for safe collaboration with humans in a shared workspace. They are typically smaller, lighter, and more flexible than their industrial counterparts. Cobots are equipped with sensors and vision systems that allow them to interact with their environment and respond to human presence.

Benefits of Cobots in Manufacturing

The integration of cobots offers a multitude of advantages:

Enhanced Productivity: Cobots can handle tedious, repetitive tasks, freeing up human workers to focus on more complex activities that require creativity and problem-solving skills. This leads to a more efficient allocation of labor and increased overall production output.

Improved Safety: Cobots are designed to be safe for human interaction. Their sensors and safety features prevent accidental collisions and injuries, creating a safer work environment for human workers.

Increased Versatility: Cobots are typically easier to program and redeploy compared to traditional robots. This allows for greater flexibility in production lines, adapting to changing requirements and new product designs.

Reduced Costs: Cobots often have lower upfront costs and require less maintenance compared to industrial robots. Additionally, the reduction in workplace injuries and improved efficiency can translate to significant cost savings.

Human-AI Interaction: A Collaborative Dance

Successful cobot implementation hinges on effective human-AI interaction:

Clearly Defined Roles: It's crucial to clearly define the roles of humans and cobots within the manufacturing process. This ensures smooth collaboration and avoids redundancy of effort.

Intuitive Interfaces: Cobots should be equipped with user-friendly interfaces that allow for easy programming and operation by human workers, even those without extensive technical expertise.

Seamless Communication: Effective communication between humans and cobots is essential. This might involve visual cues, audio signals, or even natural language processing to ensure both parties understand each other's actions and intentions.

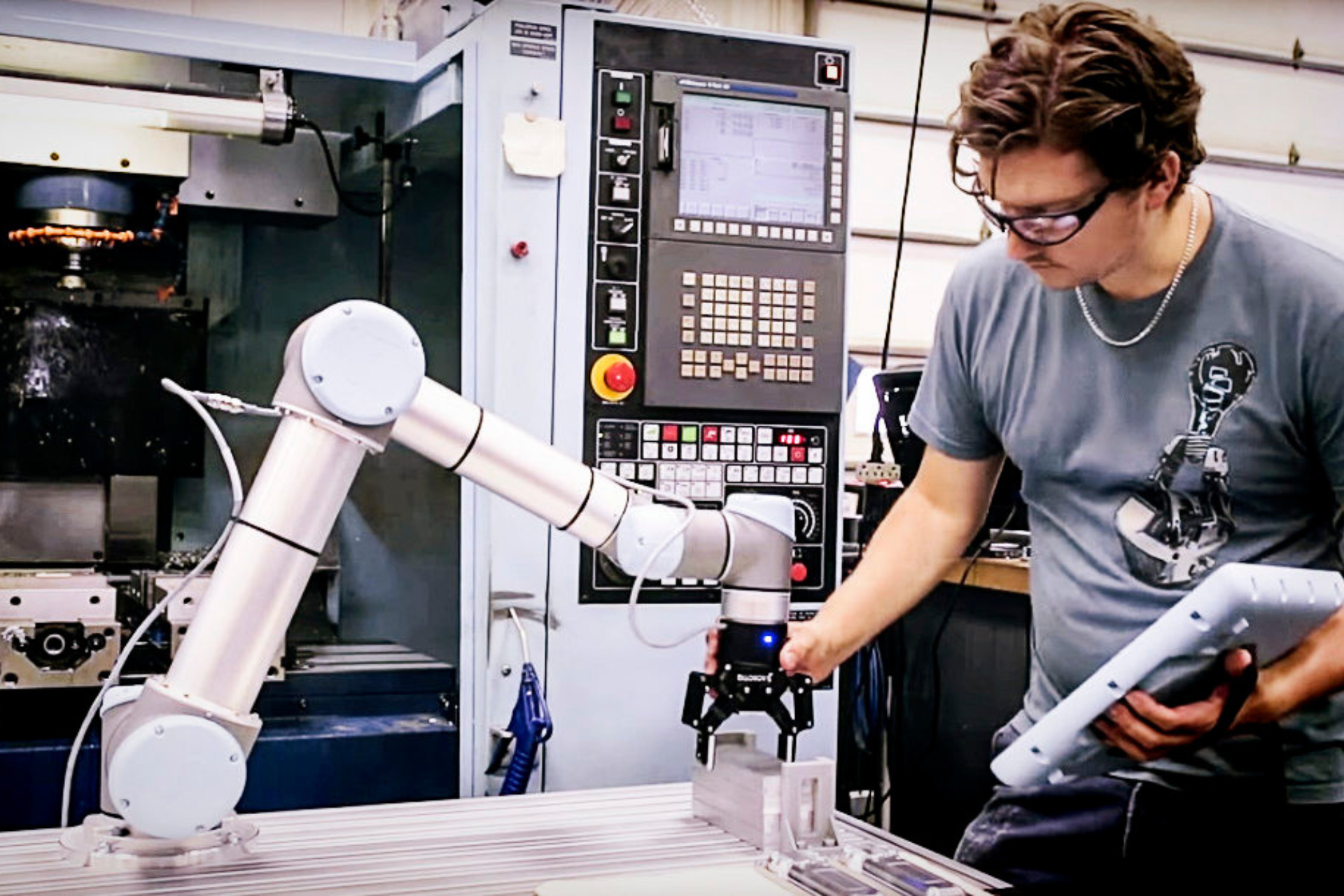

Examples of Cobot Applications in Manufacturing

Cobots are making their mark across various manufacturing processes:

Assembly Lines: Cobots can assist with tasks like parts handling, feeding materials, and sub-assembly, reducing worker fatigue and improving assembly line efficiency.

Quality Control: Cobots equipped with vision systems can perform visual inspections, identifying defects with high accuracy and freeing up human inspectors for more complex quality checks.

Packaging and Palletizing: Cobots can handle repetitive tasks like product packaging and palletizing, reducing the physical strain on human workers and improving packaging consistency.

Challenges and Considerations

Initial Investment: Although cobots may offer long-term cost savings, the upfront investment in cobot technology and system integration needs to be carefully considered.

Job Displacement Concerns: The introduction of cobots may raise concerns about job displacement in manufacturing. However, cobots are more likely to complement human workers and create new opportunities requiring technical skills for cobot programming and maintenance.

Training and Development: Upskilling the workforce to work effectively alongside cobots is crucial. Training programs need to be developed to equip workers with the necessary skills for human-AI collaboration.

The Future of Collaborative Manufacturing

Cobots represent a significant step towards a future of collaborative manufacturing. As AI and robotics technology continue to evolve, we can expect to see:

Advanced Cobot Capabilities: Cobots are likely to become more sophisticated, with improved dexterity, artificial intelligence, and the ability to handle a wider range of tasks.

Enhanced Human-AI Interaction: The communication and collaboration between humans and cobots will become more seamless, fostering a truly integrated work environment.

Focus on Human-centric Design: Cobot design will emphasize safety, ease of use, and intuitive interfaces, ensuring a positive and productive human-AI interaction experience.

In conclusion, Collaborative robots are not here to replace human workers, but rather to work alongside them, amplifying human capabilities and ushering in a new era of intelligent manufacturing. By embracing this evolving human-AI interaction, factories can achieve greater efficiency, safety, and ultimately, a more competitive edge in the global marketplace.